Our Products.

Our Products.

A Deeper Dive

Injection Moulding Machines | JSW

We supply a vast range of all electric injection moulding machines, specialising in the supply of machines for bespoke problems no other competitor can supply.

Some of these include:

Small to ultra large horizontal machines

Vertical non and Rotary table

Rubber, Magnesium, Ultra high injection, Optical Lens, Gas Injection, Thermosetting, Multi-colour/material, Injection press, Direct press and Multi-layer blow moulding

Industry use: Medical, Healthcare, Electronics, Connectors, Plumbing, Automotive, Packaging.

Size: Clamping force 30 - 3,000 Tonnes

Fastest delivery time: 2-4 weeks

Hot Runners | Seiki

Hot runner systems loose heat during production, but significantly at the gate area due a cooler temperature change at the cavity.

When standard hot runner probes fitted with only 1 body temperature control are turned up high to account for this change in temperature at the gate, the molten plastic situated away from the cavity begins to overheat, causing a hot spot. This causes a snowball of connected issues - gas trap, burn marks, reduced productivity and loss of material strength/product quality.

Uniquely patented - Seiki’s hot runner systems are fitted with 2 independent temperature controls - 1 for the main body (that can be used with any existing controller) and 1 for the separate tip at the gate, this enables engineers to have increased control of temperature only at the gate where its needed. Preventing overheating in the main body and therefore eliminating degradation altogether.

Product types include:

Hot Runner - probe and valve gate

Runnerless Rubber and LSR Moulding System

Gate Tip Temperature Controller

Manifolder

Hothalf

Industry use: Medical, Healthcare, Electronics, Connectors, Plumbing, Automotive, Packaging.

Fastest delivery time: 4-6 Weeks

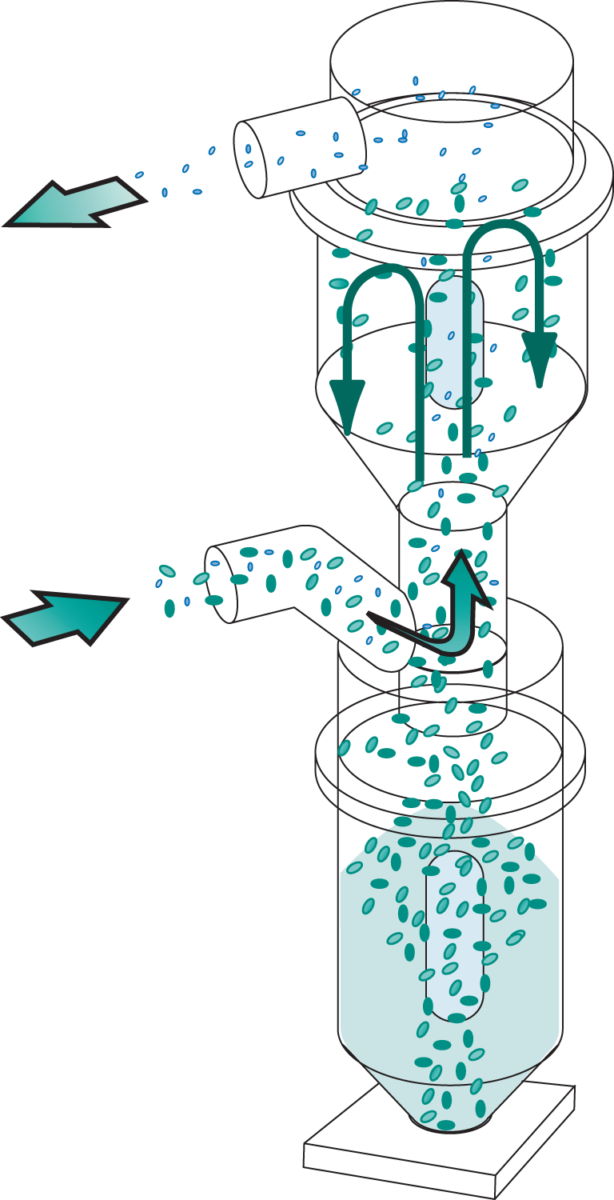

Dryers | Matsui

In a standard drying system - air from the atmosphere is dried by being pushed through a bed of desiccant beads to remove air moisture. The space between the desiccant beads limits the air volume being passed through, and overtime this desiccant becomes saturated with moisture and needs to be swapped out for a new batch to continue the drying process. This creates variability of moisture throughout the drying process and means plastic material has to be dried 2 or 3 times longer to eliminate silver streak rejects.

During operation the desiccant beads also vibrate, breaking down the desiccant material which transfers into the plastic during production and causes rejects.

Separately, conventional loading systems, that transfer the plastic from the dryer to the injection moulding machines hopper does not filter the fines or dust which naturally forms in the plastic material. This dust transfers into the plasticising process and onto the screw where it burns causing black speck rejects.

Matsui’s unique plug and play drying system has a world first drying cylinder built up of a large network of honeycomb shapes channels coated in baked on microscopic desiccant. The benefit of this large network of channels means a greater quantity of air can be dried, resulting in half the plastic material drying time. The cylinder rotates slowly and continuously through a series of zones - ‘drying’, ‘regenerating’ and ‘cooling’, meaning the desiccant never becomes saturated with moisture and the air moisture level is stable and constant, resulting in stable product quality.

As Matsui’s drying rotor uses a bonded desiccant that does not vibrate during operation and never needs to be swapped in a batch process, meaning zero desiccant contaminant can pass into the product to cause rejects, no batch process saves engineers time and the lifetime of the honeycomb dessicant is typically 20 years.

Lastly, built into the drying system is a material loading hopper which removes all dust and fines during the transportation of the plastic material from the dryer to the moulding machine hopper, eliminated black speck rejects.

Matsui’s system also successfully recaptured heat from the process which is reused and in-turns also saves on energy.

Some of these include:

Portable plug-and-play dryers

Thermal conduction vacuums

Grinders and Granulators

Widerange and water temperature controllers

Loaders and Aerohoppers

Blenders

Material handling

Mold ventilation

Thermal balance

Industry use: Medical, Healthcare, Electronics, Connectors, Plumbing, Automotive, Packaging.

Fastest delivery time: 2-4 weeks